Knowledge about mopa laser marking machine

Mopa laser marking machine is a specially designed machine that is used to mark on materials such as metals, plastics, leather, and glass, among others. It is known as a marking machine because it can engrave, inscribe or mark on the surfaces of the materials.

The machine uses a fiber laser that emits a laser beam at a particular wavelength, which is then modulated by a Mopa fiber laser source. The Mopa laser source provides greater flexibility in controlling the pulse width, frequency, and power of the laser beam. This ensures that the laser beam’s output is stable, precise, and accurate, making it ideal for high-quality marking and engraving.

The Mopa laser marking machine is easy to use and has a low maintenance cost. It provides a non-contact marking process, which eliminates any damage to the surface of the material being marked. The machine is also very durable and can operate continuously for several hours without any need for downtime.

The Mopa laser marking machine is widely used in industries such as automotive, aerospace, medical, and electronics. It is perfect for marking serial numbers, logos, barcodes, and other identification markings on various products.

In conclusion, the Mopa laser marking machine is a high-performance machine that uses modern technology to provide accurate, precise, and high-quality markings. It is ideal for use in many industries, and its ease of use and low maintenance cost make it a popular choice for marking, engraving, and inscribing materials.

Various Types of mopa laser marking machine

Mopa laser marking machines are highly advanced pieces of equipment that utilize mopa laser technology to produce high-quality and long-lasting markings on various materials. The mopa laser technology has revolutionized the world of marking and engraving with its versatile capabilities that allow users to adjust the pulse duration and frequency of the laser beam. Here are various types of mopa laser marking machines:

1. Portable Mopa Laser Marking Machine

This type of laser marking machine is designed for on-site marking and can be easily carried around. It is a great option for industries that require making prototypes on the production line.

2. Fiber Mopa Laser Marking Machine

Fiber Mopa laser machines are highly efficient, versatile, and can be used on a wide range of materials, including metals, plastics, and ceramics. The fiber laser beam generated through the machine’s optical fiber has high energy density and provides excellent precision.

3. Co2 Mopa Laser Marking Machine

Co2 mopa laser marking machines are ideal for applications that require high marking speed and deep engraving on non-metal materials such as wood, acrylic, glass, paper, and plastics. This type of machine uses a Co2 laser source with a wavelength of 10.6μ to produce markings.

4. UV Mopa Laser Marking Machine

The UV Mopa laser marking machine is perfect for use on materials that cannot handle high temperatures, including glass, plastic, and electronic components. It produces high-resolution, long-lasting marks on the surface of the material and is ideal for use in electronic manufacturing, medical, and cosmetic industries.

5. 3D Mopa Laser Marking Machine

This type of laser marking machine is designed to work on 3D surfaces, and it uses a 3D scanner to scan the surface of the material before engraving. This machine is ideal for use in the manufacturing of complex and customized products.

In conclusion, mopa laser marking machines are highly advanced and versatile pieces of equipment featuring cutting-edge technological capabilities. These machines are highly efficient and suitable for a wide range of industries, including automotive, aerospace, construction, and medical.

FAQ sourcing mopa laser marking machine manufacturer from China with multiple answers

Q: What is a mopa laser marking machine?

A: A mopa laser marking machine is a type of laser marking machine that uses a mopa fiber laser as the laser source. The mopa laser can produce a wider range of pulse durations, which makes it suitable for marking materials with different colors and textures.

Q: Why would I need a mopa laser marking machine?

A: A mopa laser marking machine is ideal for marking materials that are difficult to mark using traditional laser marking machines such as stainless steel, titanium, brass, and other highly reflective metals. It can also be used to mark plastics, ceramics, and other non-metallic materials.

Q: What are the benefits of using a mopa laser marking machine?

A: The benefits of using a mopa laser marking machine include higher precision, faster marking speeds, and versatility in marking different materials. The machine also reduces the risk of damaging the material being marked since it uses a controlled laser beam.

Q: What are the applications of a mopa laser marking machine?

A: The applications of a mopa laser marking machine include marking logos, serial numbers, product names, and barcodes on products in various industries like aerospace, automotive, engineering, jewelry, medical, and electronics.

Q: How can I source a reliable mopa laser marking machine manufacturer from China?

A: You can source a reliable mopa laser marking machine manufacturer from China by conducting thorough research online, checking reviews, visiting trade shows, and asking for referrals from reliable sources. Some of the top manufacturers in China include Han’s Yueming Laser, Maxphotonics, and Raycus. It’s important to choose a manufacturer with a good reputation, quality products, excellent customer service, and competitive prices.

Applications of mopa laser marking machine

Mopa laser marking machine has been widely used in various industries due to its advanced technology and capabilities. Following are the applications of Mopa laser marking machine in different industries:

1. Automotive Industry: Mopa laser marking machines are used for marking various automobile components like engine parts, bearings, gears, and other metallic parts. The machine ensures that the marking is precise, durable, and indelible. It also helps in ensuring the traceability of these components.

2. Jewelry and Watchmaking: Mopa laser marking machine is used to engrave high-quality logos, serial numbers, and other designs on jewelry items and watches. The machine is suitable for marking on different types of materials such as gold, silver, platinum, and diamonds.

3. Aerospace and Defense Industry: The Mopa laser marking machine is used for marking serial numbers, barcodes, identification numbers, and other markings on parts used in the aerospace and defense industry. These marks are permanent, tamper-proof, and can withstand harsh environmental conditions.

4. Medical Devices: Mopa laser marking machines are used for marking instruments, implants, and other devices used in the medical industry. The machine ensures that the marking is precise, clean, and sterile.

5. Electronic Components: Mopa laser marking machines are used for marking logos, serial numbers, barcodes, and other markings on electronic components such as PCBs, ICs, and chipsets. The machine can mark on various materials such as plastic, metal, and ceramics.

6. Packaging Industry: Mopa laser marking machine is used for marking codes, barcodes, and logos on different types of packaging materials like cardboard, plastic, and glass. The machine can mark on both flat and curved surfaces with high accuracy.

In conclusion, Mopa laser marking machine is widely used in various industries such as automotive, jewelry, aerospace, medical, electronic components, and packaging industry to mark and engrave precise, permanent, and indelible markings on different materials.

Manufactured Products made of mopa laser marking machine

Mopa laser marking machines are used extensively in many industries to create high-quality, precise markings on various materials. Some of the commonly manufactured products using Mopa laser marking machines are:

1. Electronic Components: Mopa laser marking machines can be used to mark unique identification codes, logos, and barcodes on electronic components such as microchips, PCBs, and electronic appliances.

2. Medical Devices: Mopa laser marking machines can mark medical devices with serial numbers, manufacturer information, and logos. The markings are long-lasting and resistant to wear, making it easy to track the devices and prevent counterfeiting.

3. Jewelry: Mopa laser marking machines can create intricate and precise markings on jewelry items made of precious metals like gold, silver, or platinum. The machine can engrave texts, logos, designs, and other details with perfect accuracy, enhancing the beauty of the jewelry.

4. Automotive Parts: Automotive parts made of metal, plastic, or rubber can be marked with Mopa laser marking machines to add identification numbers, warning signs, and other markings necessary for quality control measures in the automotive industry.

5. Aerospace Components: High-precision markings are required in the aerospace industry to ensure each component is traceable and meets industry standards. Mopa laser marking machines enable aerospace manufacturers to produce high-quality markings on a range of materials, including composites, titanium, and aluminum.

6. Promotional Items: Mopa laser marking machines can be used to create personalized and unique promotional products like keychains, USB drives, and other giveaways. The high-quality markings give the items a professional look and make them stand out in a sea of generic promotional items.

In conclusion, Mopa laser marking machines are essential tools used in various industries to mark products with high precision, making them suitable for the intended use. The machines enable manufacturers to create unique, long-lasting markings on a variety of materials used in different industries.

The Process of mopa laser marking machine

MOPA laser marking machine is an advanced laser marking technology used for marking different materials, including metals, plastics, and other materials. The MOPA laser marking machine uses an advanced laser source with a Master Oscillator Power Amplifier (MOPA) technology to produce high-quality marking with greater speed, accuracy, and flexibility.

The process of the MOPA laser marking machine involves several steps. Firstly, the material to be marked is placed on the marking platform. The software is then used to select the required parameters like the marking speed, power, and wavelength. The laser beam is then focused on the material and the marking process begins.

The marking process involves the use of laser beams that are modulated to produce various patterns and shapes on the material surface. The MOPA laser marking machine uses a high-speed scanning system that produces accurate markings on the material. The machine also uses a computer-controlled cooling system to maintain the temperature of the laser source, preventing overheating and ensuring high-quality marking.

The MOPA laser marking technology offers several advantages over traditional laser marking machines. It provides greater flexibility in marking different materials with different colors and patterns. The MOPA laser marking machine can also mark highly reflective materials that cannot be marked by ordinary laser marking machines. The technology also enables a higher level of precision and accuracy in the marking process.

In conclusion, the MOPA laser marking machine is an advanced technology that uses a combination of laser beam modulation, high-speed scanning, and computer control to produce high-quality markings on different materials. The technology offers greater flexibility, precision, and accuracy in the marking process, and can be used in various industries that require high-quality and reliable marking solutions.

How to use mopa laser marking machine

Mopa laser marking machine is a versatile, high-precision laser marking device used for permanent labeling and printing on a variety of materials such as metals, plastics, ceramics, and others. Mopa technology is a unique feature that allows the laser to adjust pulse width and frequency independently.

Here are some basic steps on how to use Mopa laser marking machine:

1. Prepare the material for marking: Ensure that the material to be marked is clean and dry and free of any oil or debris that may reduce the quality of the marking.

2. Create the marking design: Use design software to create the design you want to be marked, save it, and transfer it to the laser marking software.

3. Set up the laser parameters: Set up the laser parameters such as the laser power, frequency, pulse width, and marking speed. These settings should be adjusted according to the material to be marked and the desired marking results.

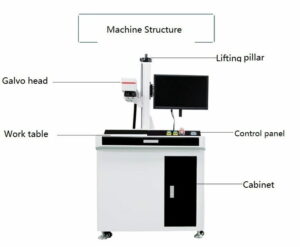

4. Load the material onto the marking bed: Place the material to be marked onto the marking bed of the laser marking machine. Adjust the height of the marking bed, so that the laser can focus on the material correctly.

5. Begin the marking: Press the “start” button on the laser marking software, and the marking process will begin. The Mopa laser marking machine will engrave the material using the settings you have specified.

6. Quality check: Once the marking process is complete, check the quality of the marking to ensure that it is precise, and readable.

7. Unload the material: Once the marking process is complete, remove the material from the marking bed.

In summary, using a Mopa laser marking machine involves preparing the material, designing the marking, adjusting the laser parameters, loading the material to be marked, starting the marking process, quality checking, and unloading the material. By following these steps, you can easily mark various materials with high precision and accuracy using the Mopa laser marking machine.

Benefits of Utilizing mopa laser marking machine

There are several benefits of utilizing mopa laser marking machines in various industries. Some of these benefits include:

1. High precision: Mopa laser marking machines offer high precision marking, making it ideal for industries that require accurate and detailed marking. The machines can produce fine and clear markings on various types of surfaces, including metals, plastics, and ceramics.

2. Versatility: Mopa laser marking machines can mark a wide range of materials, from soft materials like rubber to hard metals like stainless steel. This versatility makes these machines suitable for use in various industries, such as automotive, aerospace, medical, and electronics.

3. Speed and efficiency: Mopa laser marking machines are designed for high-speed marking. This means that they are capable of producing high-quality marks quickly and efficiently, which is ideal for industries that require high output.

4. Cost-effective: Mopa laser marking machines are cost-effective, as they require little to no maintenance. Additionally, they use little power and have a longer lifespan than traditional marking methods, making them a worthwhile investment for any industry.

5. Customization: With mopa laser marking machines, users can produce custom markings that are unique to a particular product or industry. This customization capability makes these machines suitable for use in branding and marketing.

Overall, mopa laser marking machines offer a wide range of benefits to various industries. They offer high-speed marking, precision, versatility, cost-effectiveness, and customization, which are all critical factors for any business looking to enhance its production process and output.

Things to Consider When Purchasing mopa laser marking machine

When purchasing a mopa laser marking machine, there are several things to consider to ensure you’re making a wise investment. Here are some factors to keep in mind:

1. Laser source – The laser source is the heart of any laser marking machine. Ensure that the machine has a reliable, high-quality laser source that will meet your marking requirements.

2. Power – The power of the laser determines the machine’s marking speed and depth. Choose a machine with the appropriate power for your application.

3. Marking area – Consider the size of the marking area required for your application, and choose a machine that can accommodate it.

4. Accuracy – The machine’s accuracy directly affects the quality of your marking. Look for a machine that is known for its precision and accuracy.

5. Durability – A laser marking machine is a significant investment, and you want it to last a long time. Choose a machine made of durable materials that will withstand frequent use.

6. Ease of use – The machine should be easy to operate, and the layout of the software needs to be user-friendly.

7. Technical support – Look for a company that offers good technical support and responds quickly to your queries.

8. Cost – The cost of a laser marking machine varies depending on its specifications and features, and it’s essential to consider the cost relative to its expected lifespan and ROI.

By considering these factors when purchasing a mopa laser marking machine, you can ensure that you choose a machine that meets your needs and delivers excellent results.

Properties of mopa laser marking machine

MOPA laser marking machine is a highly advanced laser marking technology that offers superior marking results along with greater efficiency and versatility. It uses a pulsed fiber laser beam to create highly precise and customizable marks on a wide range of materials, including metals, plastics, ceramics, and more.

Some of the key features and properties of the MOPA laser marking machine include:

1. Adjustable pulse width: The MOPA laser marking machine offers adjustable pulse width, which allows the user to achieve highly precise and customizable marks on materials with different properties and characteristics.

2. High-speed marking: The MOPA laser marking machine can mark at high speeds, which increases productivity and helps reduce production time and costs.

3. High-contrast marks: The MOPA laser marking machine can produce highly visible, high-contrast marks that are easy to read and interpret.

4. Wide range of materials: The MOPA laser marking machine is highly versatile and can mark on a wide range of materials, including plastics, metals, ceramics, and more.

5. Low maintenance: The MOPA laser marking machine requires very little maintenance, which significantly reduces operating costs and increases uptime.

6. Long lifespan: The MOPA laser marking machine has a long lifespan, which makes it an ideal investment for businesses that require reliable and durable equipment.

7. User-friendly software: The MOPA laser marking machine comes with user-friendly software that makes it easy for users to create and customize marks to their specifications.

Overall, the MOPA laser marking machine is an advanced and versatile marking solution that offers high-quality results and increased efficiency and productivity.

Terms for mopa laser marking machine

Mopa laser marking machines are precise and versatile tools for engraving, cutting, and marking various materials such as metals, plastics, and ceramics. With the help of advanced technology, such machines operate by using a mopa laser source that provides high-quality results.

The term Mopa stands for Master Optical Power Amplifier, which is a technology that allows for more precise pulse control than traditional Q-switching methods. Mopa laser marking machines provide a wide range of customization options, making them ideal for use across multiple industries.

Some of the key terms associated with Mopa laser marking machines include:

1. Fiber Optic Laser – A type of laser that uses a fiber-optic cable to transmit the laser beam to the material being marked.

2. Pulse Duration – The length of time that the laser beam is on during each pulse. Mopa lasers offer more control over pulse duration than other types of lasers, allowing for more precise results.

3. Frequency – The number of laser pulses per second, typically measured in kilohertz (kHz). Higher frequencies result in faster marking speeds.

4. Peak Power – The maximum power output of the laser during each pulse. Mopa lasers offer higher peak powers than traditional Q-switched lasers, allowing for deeper and more precise marks.

5. Galvanometer – A device that controls the movement of the laser beam across the material being marked.

6. Marking Software – A program that allows the user to control the laser marking settings, such as pulse duration, frequency, and power.

7. Rotary Axis – An optional attachment that allows the material being marked to rotate, making it possible to mark cylindrical objects.

Mopa laser marking machines offer unparalleled flexibility and precision, making them ideal for use in a wide range of applications, including jewelry marking, electronics manufacturing, and automotive parts marking. With their advanced technology and customizable settings, Mopa lasers are quickly becoming the preferred choice for marking and engraving materials of all types.

The Evolution history of mopa laser marking machine

The MOPA laser marking machine has an interesting history of evolution. MOPA stands for Master Oscillator Power Amplifier, which refers to the way this type of laser operates. It was first developed in the 1980s, as a way to create a more efficient and powerful laser. The technology was quickly adopted by the aerospace and defense industries.

Over the years, MOPA lasers have become increasingly popular in other industries as well, such as automotive and electronics manufacturing. This is because of their ability to create precise and permanent marks on a wide range of materials, including metals, plastics, and ceramics.

The first MOPA laser marking machines were relatively bulky and expensive, but technological advancements have made them smaller, faster, and more cost-effective. This has helped to make them more accessible to a wider range of businesses.

One of the key advantages of MOPA lasers is their ability to tune the frequency and pulse duration of the laser output. This allows them to create a wider range of marking options, from fine, detailed marks to deeper and darker engravings. This flexibility has made them a popular choice for a variety of applications, including branding, identification, and product traceability.

In conclusion, MOPA laser marking machines have come a long way since their inception in the 1980s. With ongoing advancements in technology, they are likely to continue to be an important tool for businesses looking to create high-quality and durable marks on their products.

mopa laser marking machine Price

Mopa laser marking machines are known for their high precision and versatility. They are widely used in the field of metal, plastic, and glass marking. The mopa laser marking machine comes with a mopa fiber laser that offers high-speed and high-precision marking capabilities. The machine is designed to be user-friendly and easy to operate. It comes with advanced software that allows for easy customization of designs and settings.

The price of a mopa laser marking machine varies based on the model and specifications. Typically, the price of a standard mopa laser marking machine ranges between $5,000 to $20,000. However, the price can go higher for custom-built machines that feature advanced technologies and additional features.

In addition to the initial purchase price, maintenance costs should also be considered. These machines require periodic maintenance to ensure optimal performance. This can include regular cleaning and replacement of parts, which can add to the total cost of ownership.

When considering purchasing a mopa laser marking machine, it is important to select a reputable manufacturer that offers reliable products and excellent customer support. It is also recommended to compare prices from different manufacturers and distributors to find the best value for your investment.

Overall, a mopa laser marking machine is a worthwhile investment for businesses looking to enhance their product branding and identification capabilities. With its high precision and versatility, it can provide long-lasting, high-quality marking solutions for a wide range of materials and industries.