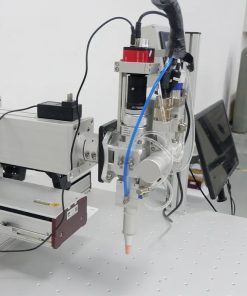

Automatic Laser Welding Machine

Automatic laser welding machine adopts a 1000-4000 watt fiber laser, which has a long service life. Its intelligent operating platform is more flexible, automated, and efficient. CCD liquid crystal monitoring and inspection system can clearly observe the product positioning and welding effect according to the red indicator. The automated welding seam positioning system tracks the shape of the weld seam in real-time and promptly corrects the position of the welding torch based on the welding bead condition to achieve laser welding with more aesthetically pleasing weld surface.